Fast turnaround on new tooling

Excellent Product Consistency

In-house backup and contingency

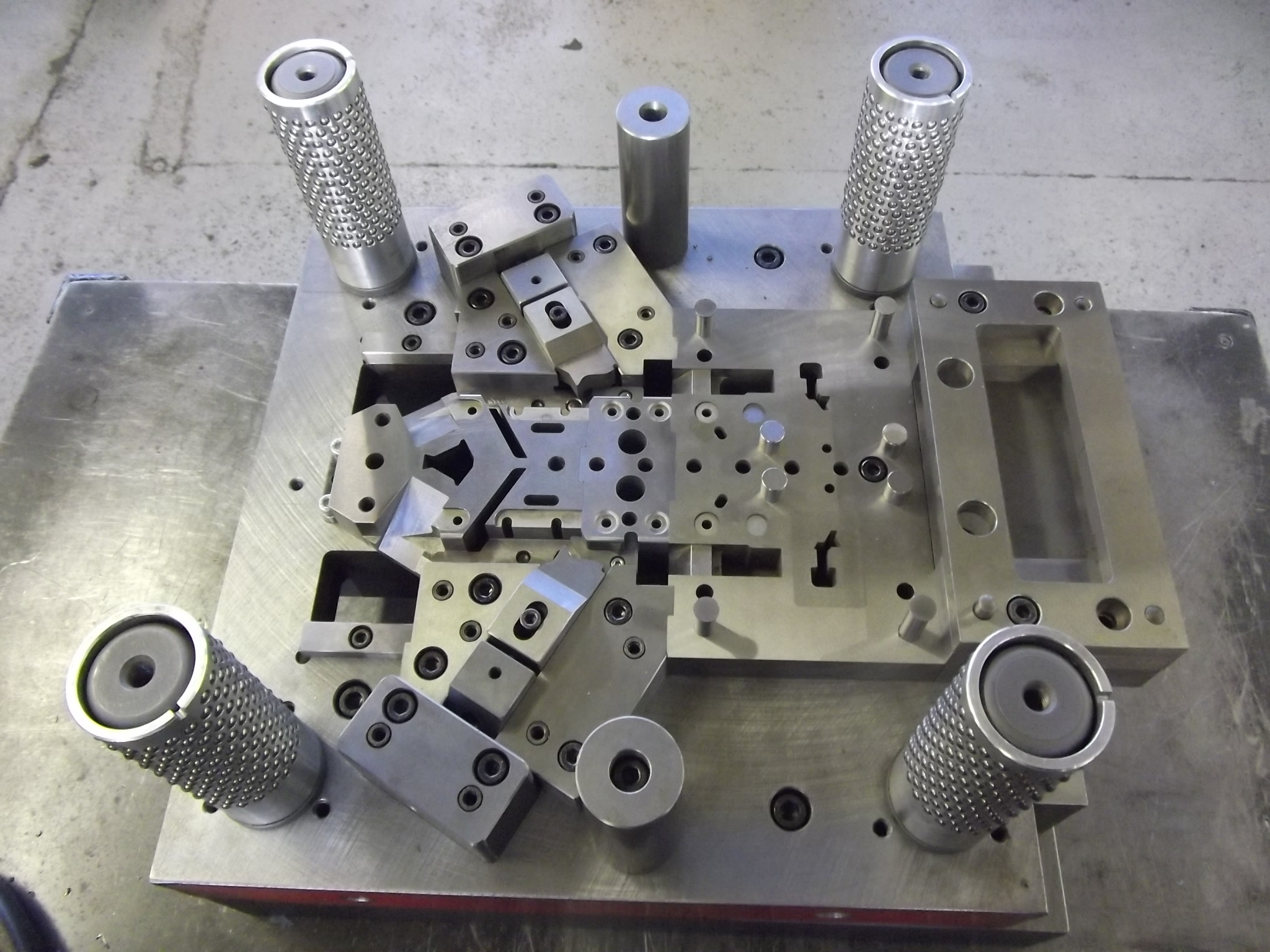

Nico Tool Room

NiCo has a highly skilled and experienced team of toolmakers operating in a large and modern tool room. Working closely with both technical design and production all tooling at Nico is designed, manufactured, serviced and repaired in house. Heat treatment of punches, dies, and inserts is carried out in the tool room to minimise turn round times, and maximum use of a “cassette” tool system for die-cast and injection mould tools is used to control costs and minimise press down times. Nico’s tooling includes:

- Press Tools

- Die Cast Tooling

- Plastic Injection Mould Tools

- Jigs, Fixtures and Gauges

The on site tool room not only keeps production running smoothly it also ensures that the quality of Nico product remains consistently high. In house tooling allows new products to reach customers far sooner, and in the unlikely event of tooling breakdown or product non conformity rebuild and rectification can be dealt with quickly.

Plant List Includes:

- Agie Classic 2S wire erosion machines

- Charmilles Roboform 20 Die-Sinker

- Hurco 900 Die Sinker

- Cincinnati Arrow 750 Machining Centre

- Bridgeport Interact 412 Machining Centre

- XYZ Programmable Mill

- Hanwha sliding head CNC lathe with automatic bar feed

- Ajax Turret Milling Machine

- Harrison M300 Lathes

- Jones & Shipman 540 Surface Grinders

- Perfect Surface Grinder

- Nabertherm Heat Treatment Ovens