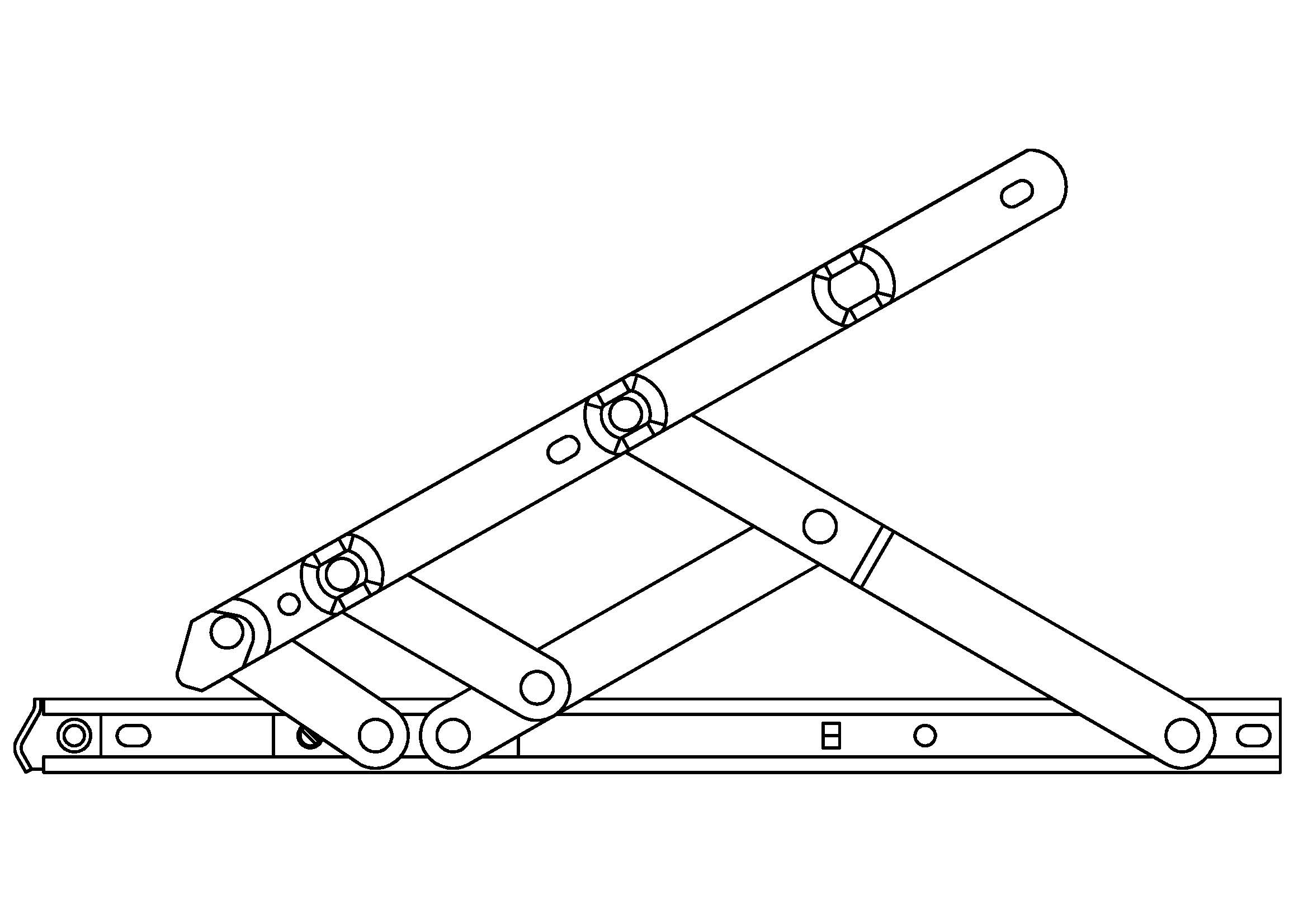

Nico Standard Hinge – 17mm

The Nico Standard Friction Hinge is designed and manufactured in the UK and has precision geometry for a smooth, positive closing action. The variable opening angles allow easy use and safe cleaning, ensuring reliable long life performance.

Features & Benefits

- Stainless Steel riveted nose cap for strength and reliability

- 3 stage counterbore process for improved resistance to wear

- Glass reinforced nylon slide eliminating breaking and wear

- 4.8mm Stainless Steel rivets for improved load carrying

- Stainless construction for exceptional corrosion resistance

- Brass adjustment screw for adjustable friction

- 10 year mechanical guarantee

Testing & Technical

- Made in Britain to an ISO 9001 Quality System

- Successfully security tested with Nico Xtra Bolts as a critical component within PAS 24 : 2016

- Secured By Design Approved as a Police Preferred Specification

- Successfully cycle tested as a critical component within BS EN 6375 Pt 2 ( Resistance to repeated opening and closing )

- Successfully weather tested as a critical component within BS EN 6375 Pt 1 ( Air, wind and water testing )

- Can comply with BS8213-1:2004 for Easy Cleaning ( size and profile dependent )

Nico hinges have been endurance tested with their maximum load carrying capacity to 3 times the British Standard requirement.

Technical Data

The Nico Standard Friction Hinge is manufactured in stainless steel and offers excellent load bearing characteristics. The 17mm stack height hinge is a non symmetrical handed stay. Slotted fixing holes in the base channel and sash bar, with a final fixing hole in each component, provide maximum sash/frame adjustment. The all metal end-cap is riveted on to the hinge for extra strength and rivet holes are counterbored in a 3 stage manufacturing process. This means parts are manufactured to tight tolerances and ensures extremely reliable operation of the finished hinges.

Fitting instructions for Nico Friction Hinges are provided in the Standard Friction Hinges pdf and the Friction Hinge Fitting Guide link in related downloads.

Size |

200mm (8″) |

250mm (10″) |

300mm (12″) |

400mm (16″) |

500mm (20″) |

600mm (24″) |

| Vent Type | Top Hung | Top Hung | Top Hung | Top Hung | Top Hung | Top Hung |

| Max. Vent Height | 350mm | 450mm | 550mm | 750mm | 1000mm | 1300mm |

| Max. Vent Weight | 12kg | 16kg | 22kg | 26kg | 28kg | 40kg |

| Opening Angle | 60° | 65° | 60° | 60° | 52° | 38° |

| Bulk Packed | 25 | 50 | 50 | 50 | 25 | 25 |

| Part No. Left | 8210L | 8220L | 8230L | 8245L | 8250L | 8260L |

| Part No. Right | 8210R | 8220R | 8230R | 8245R | 8250R | 8260R |

Size |

200mm (8″) |

250mm (10″) |

300mm (12″) |

400mm (16″) |

||

| Vent Type | Side Hung | Side Hung | Side Hung | Side Hung | ||

| Max. Vent Width | 350mm | 450mm | 600mm | 700mm | ||

| Max. Vent Weight | 12kg | 16kg | 22kg | 26kg | ||

| Opening Angle | 60° | 65° | 60° | 60° | ||

| Bulk Packed | 25 | 50 | 50 | 50 | ||

| Part No. Left | 8210L | 8220L | 8235L | 8240L | ||

| Part No. Right | 8210R | 8220R | 8235R | 8240R |